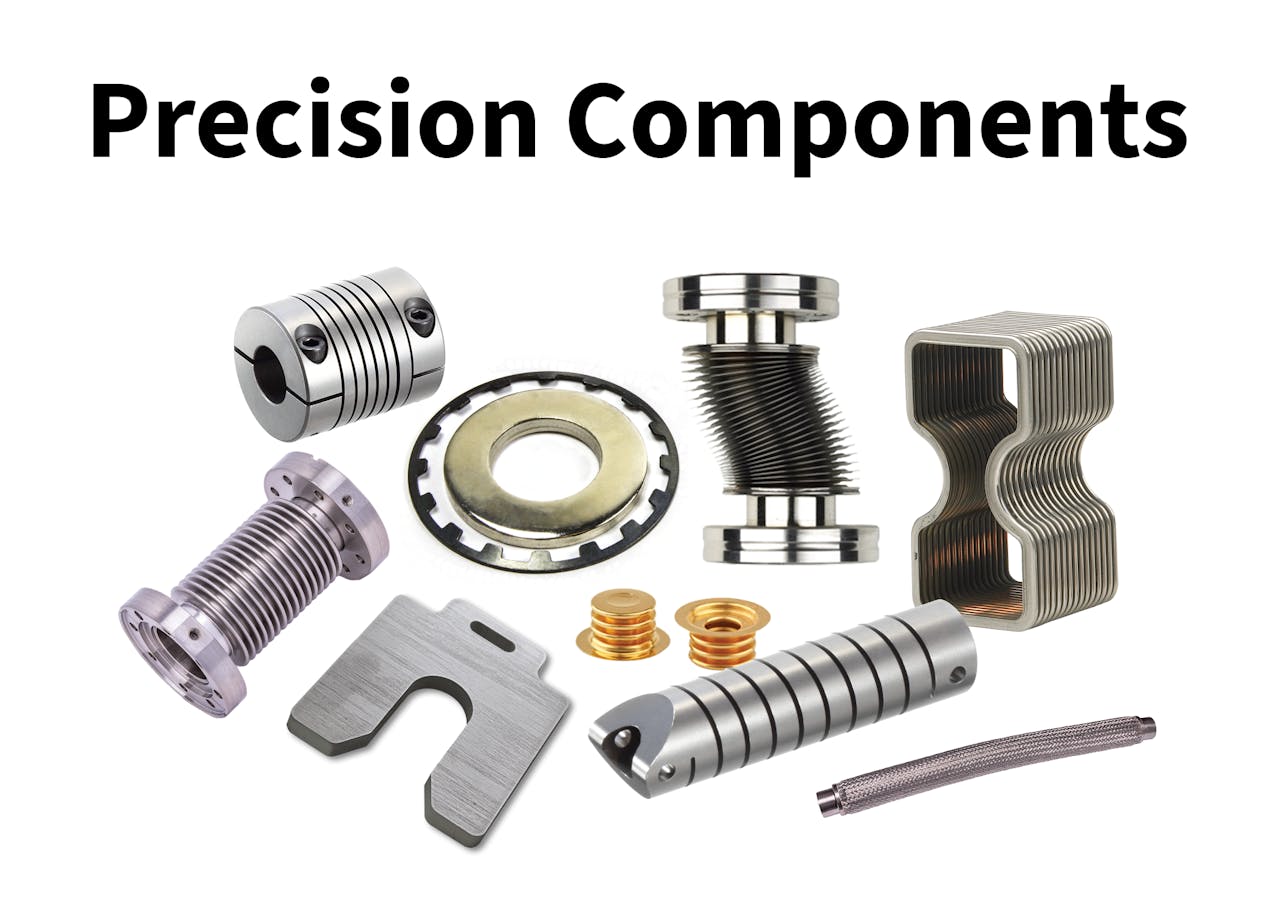

Metal Component Manufacturing

MW Components offers next day shipping on most stock parts and expansive custom manufacturing capabilities with 24-hour quote response and engineering support. With over two dozen specialized manufacturing facilities across the USA, we offer the most reliable source for high quality precision parts ranging from springs and fasteners to bellows, shims, and more.

Trusted by Brands Worldwide

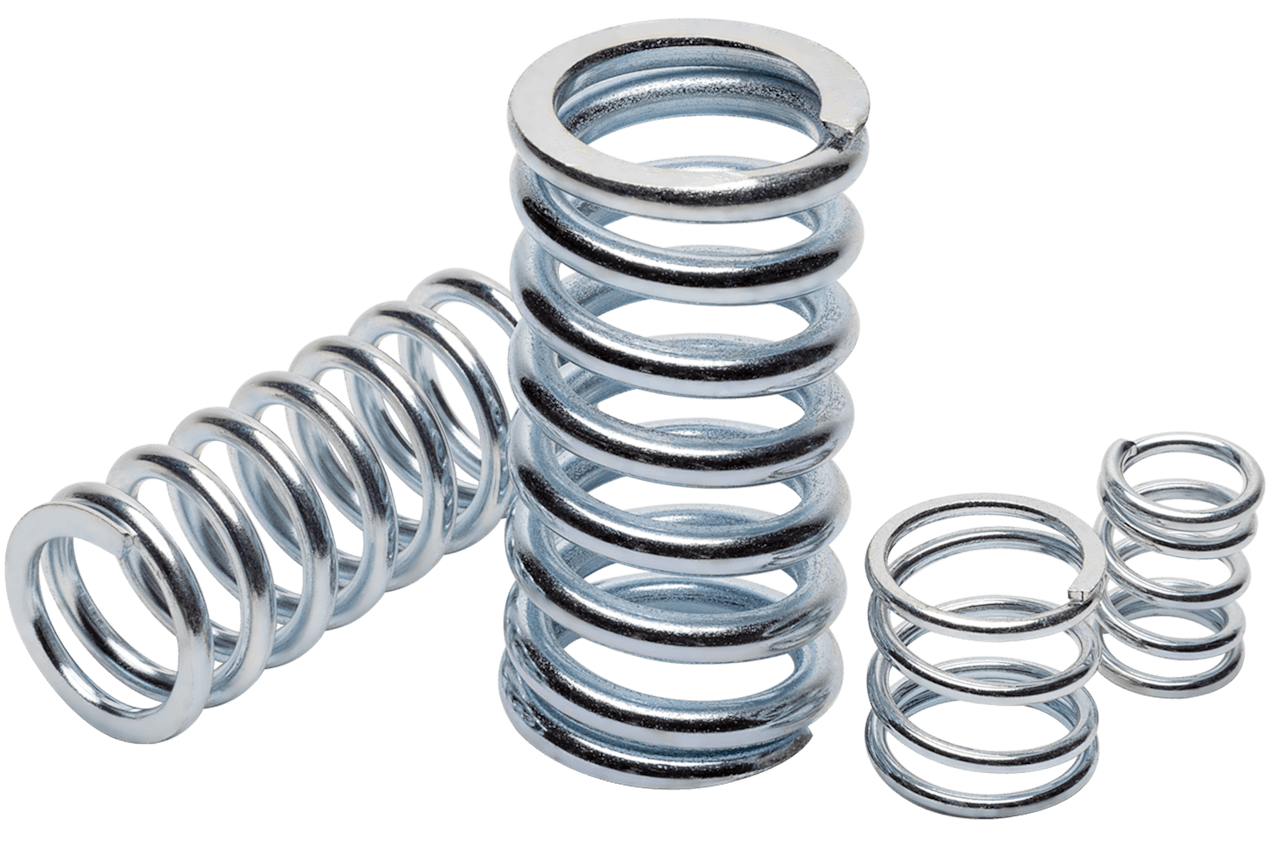

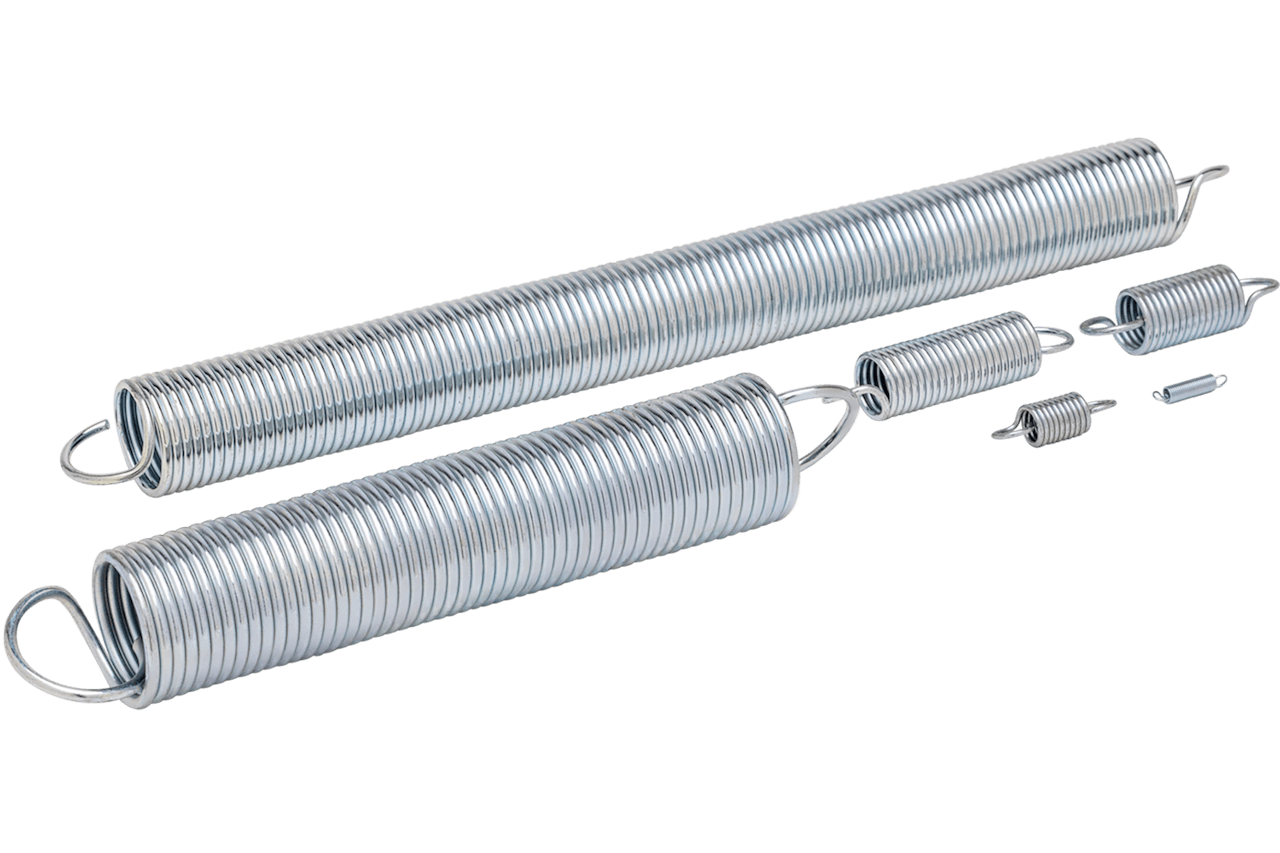

Shop 40,000+ In-Stock Designs and Ready-to-Assemble Products

Get Custom Parts Made to Spec

Stock or standard doesn't fit your needs? We manufacture custom springs, wire forms, and precision components to your specifications. Explore our full range of products or try our compression spring calculator to get the design data you need for custom springs.

What Our Customers Are Saying

Industries

Whether you're working in aerospace, energy, or agriculture, you know that the smallest parts can make the biggest difference. So do we. It's why we offer one of the largest made-in-the-USA suite of manufacturing services available for mission-critical parts with industry-specific quality processes.

Talk to our design experts about how to improve performance and reduce your timeline

Work with manufacturing professionals to choose the right processes to make the highest-quality parts

Get products made to industry specs whether that's AS9100D or API 20E

Aerospace

We are ISO9001, AS9100D, FAA, DoD, NASA, and ITAR compliant, among others. We can help with aerospace springs, fasteners, bellows, and much more.

Military & Defense

DFARS, QSLM Class 2 &3, Mil-Spec, and more. See how we can help with military vehicle suspension components, fasteners, sensing components, and other parts.

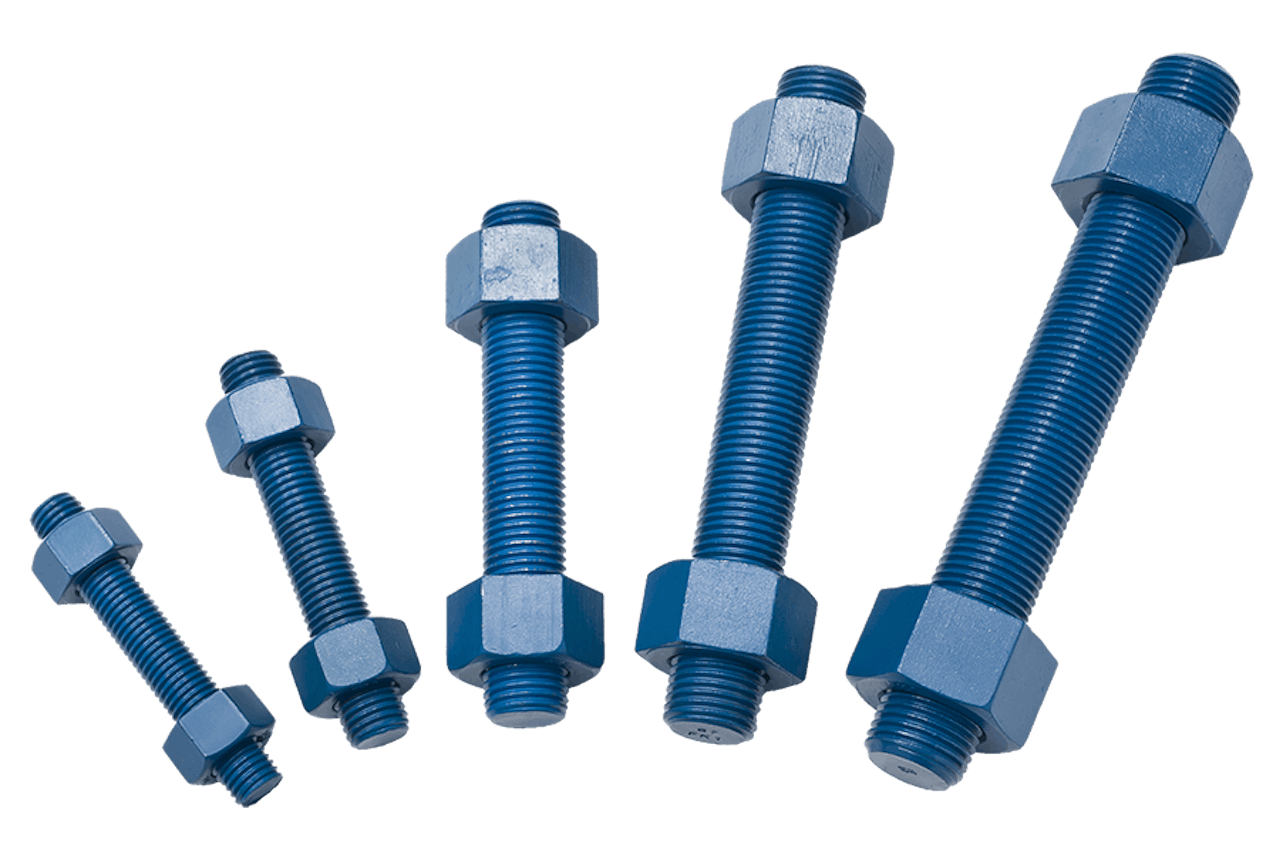

Energy, Oil & Gas

API 20E, ISO 9001, ANSI / ASME SPPE-1, and other certifications. We provide corrosion-resistant parts for hard conditions, including downhole environments.

Medical

Whether you need 316 stainless steel springs, pharmaceutical screws, or micro-components, we offer the high quality, reliable medical components.

Resources

Created by engineers, for engineers. Always free.

Need to talk to someone instead? Fill out this form with your question and we'll connect you with the engineer with the best skills to help.

Start Your Project

Get your project moving today. Contact us for a quote on a custom part, pricing, lead time, or other questions. Our team will get back to you within 1-2 hours on business days, and will be sure to route you to the best person to support your needs.