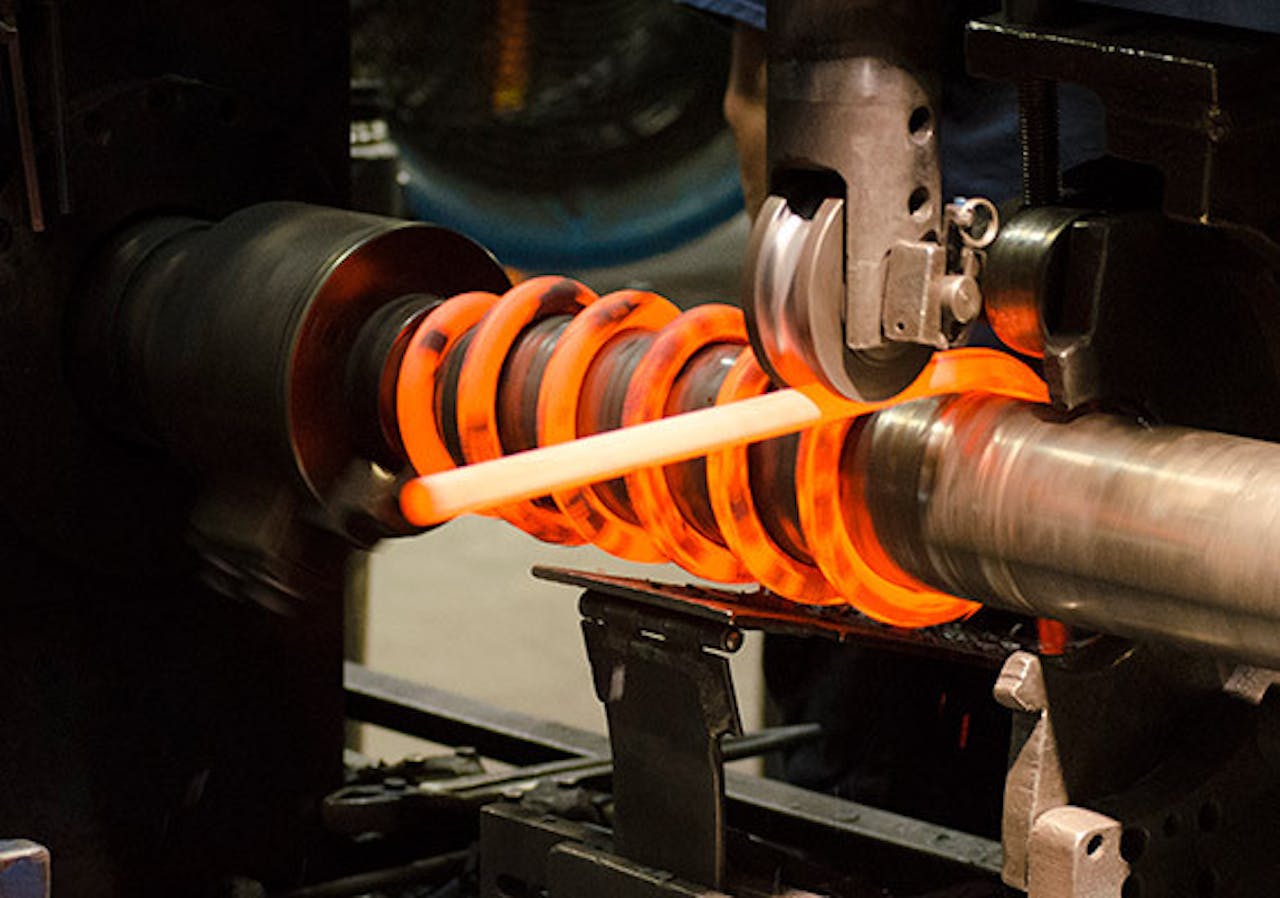

MW has been producing hot wound springs for over 70 years. Also known as hot coil springs, hot compression springs, or hot helical springs, hot wound springs are ideal for large springs or large wire diameter springs that are difficult to form from cold material.

Our Greer: Springs location, formerly known as Duer Carolina Coil, is known for their ability to support the design and manufacturing of hot wound springs. Their in-house engineering team can help answer questions and solve difficult challenges to ensure you get the highest performing, most cost-effective product possible.

Greer: Springs and MW share a commitment to quality, technology, process improvement and customers. We tightly control metallurgical processes to guarantee part quality to our customers, earning us a TS 16949 certification, among others. This guarantees the best delivery and the most competitive pricing. Contact us today for help with design needs or to request a quote for your part. You can also download the brochure for more information.

About Hot Wound Springs

Characteristics

Hot wound springs are produced by heating the metal (generally steel), forming it into the desired shape, and tempering it to the preferred specifications. Hot wound springs are preferred when larger steel springs are needed since steel in its natural state is difficult to form in larger applications without cracking.

Application & Industries

Hot wound springs are generally found in larger applications like vehicle suspensions, valve actuators, and in large trucks and outdoor equipment. They are used in several industries, some of which include, agriculture, automotive, construction, military, petrochemical, valves, and mining.

Hot Wound Spring Quality Certifications

CUSTOM MANUFACTURING

Custom Hot Wound Springs

MW Components is not limited solely to manufacturing. We also specialize in prototyping, design assistance, tooling, and more. Working with your team and preferred specifications, we will help you develop the best product for your application.

Current lead times for most hot coil spring products are just 2-6 weeks. Request a quote for details or to get more information on our design and engineering support.

Hot Wound Spring Manufacturing

MW is a leader in the spring manufacturing industry. We provide standard and specialty processes to ensure your requested product meets your quality and life cycle goals. Some examples include shot peening for improved fatigue life, load testing, individual part identification, grinding, special coatings, in-house powder coatings, cycle testing of finished products, and magnetic particle inspection.

Our highly trained staff of engineers and specialists are always on hand to meet your design, development, and manufacturing specifications. As always, our goal is to meet or exceed your every expectation.

Quality Standards & Certifications

At MW, we pride ourselves on creating quality products that meet or exceed industry standards. Not only do our facilities perform rigorous quality assurance testing to your specified ranges, but we also maintain several key certifications to ensure that only the best products are shipped to you.

Our Manufacturing Locations

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.