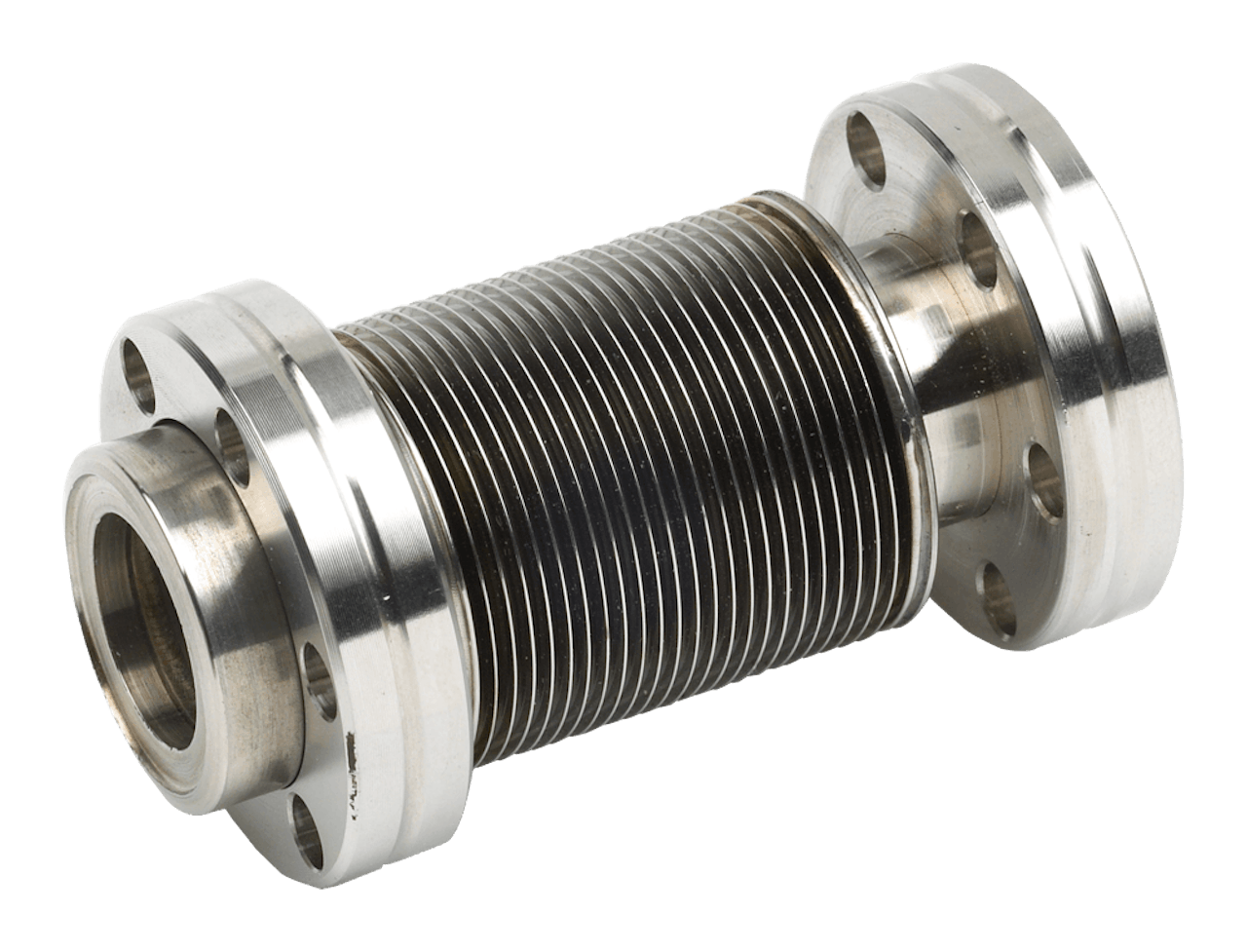

Precision-Engineered Metal Bellows

A metal bellows is a precision-engineered, flexible metal component that acts as a leak-tight seal– effectively separating two environments from one another. These versatile parts can convert changes in pressure, temperature, and position into linear motion and be used for rotary transmission that maintains flexible mechanical and electrical connections.

Metal bellows products are used in a wide variety of industrial and mechanical applications and are designed to compress, extend, or bend to absorb axial and angular movement. Some examples of useful applications for metal bellows include actuators, beamlines, expansion joints, mechanical seals, pumps, valve seals, thermal expansion tanks, reservoirs, and more.

Need custom bellows? Fill in the custom bellows design form and we'll get in touch.

Or contact our engineering team. Our expert team can answer questions and provide design support.

CUSTOM MANUFACTURING

Custom Metal Bellows

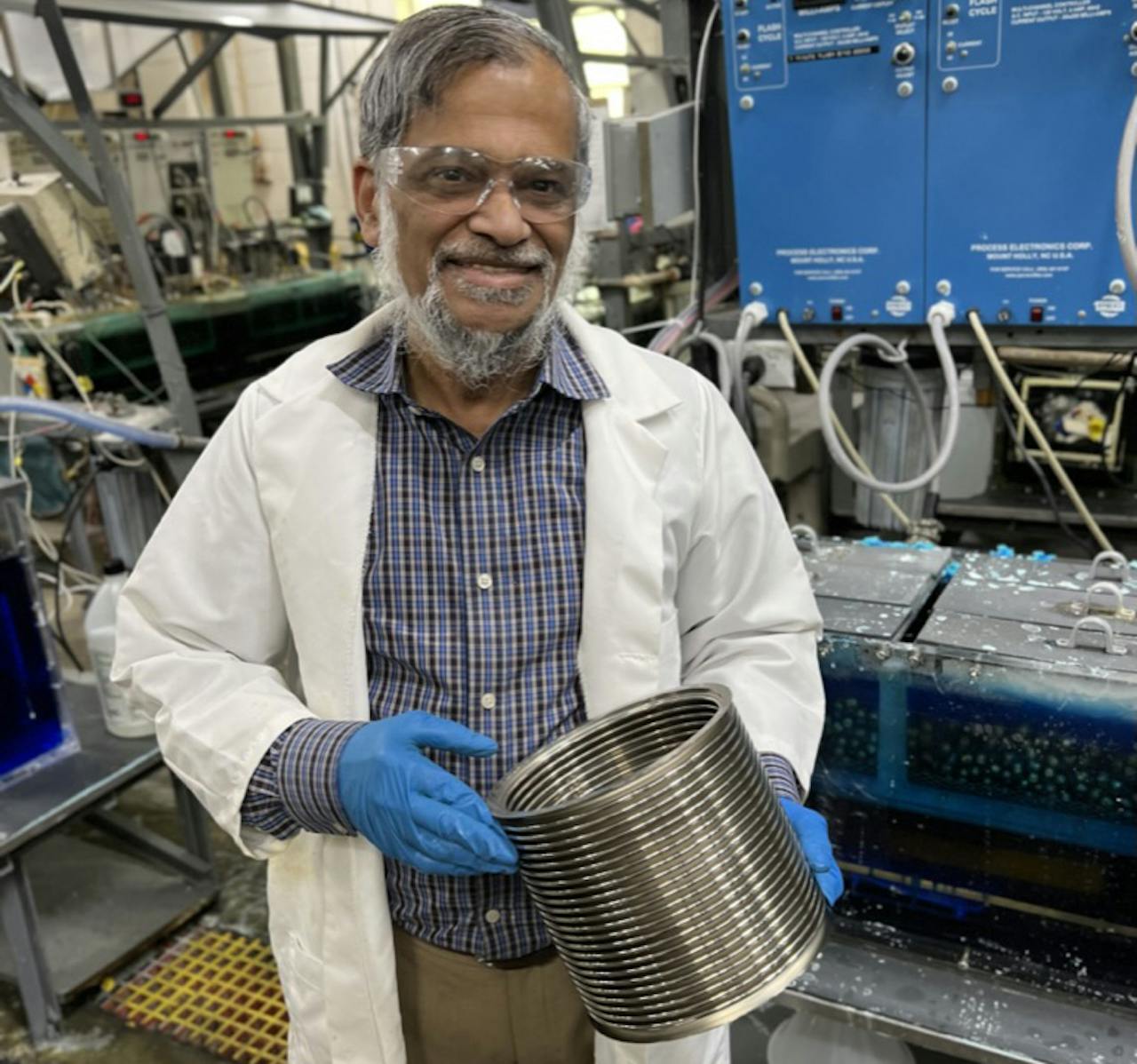

The construction method, the thickness of the walls, configuration, convolution length, spring rate, leak tightness, and the materials and finishes used all work together to supply the right amount of flexibility for your needs. MW Components has experience developing precision metal bellows across many applications and industries from vacuum bellows and sealing applications to cryogenics, aerospace, and many others. We also offer expert engineering and design assistance to provide the metal bellows that will perfectly support your application. We also produce non-standard sizes and configurations, including oval and rectangular metal bellows, and work with a variety of raw materials to suit your performance needs.

Send us your specs or configure a part.

Metal Bellows Resources & Applications

Metal Bellows Manufacturing

Metal bellows are available from MW Components in three varieties, which are differentiated by their fabrication method; these include edge-welded bellows, electrodeposited bellows, and hydroformed bellows. MW Components produces precision custom metal bellows using all three of these fabrication methods.

Click on each link below to view details for each process or view our bellows technology comparison guide for a side-by-side comparison.

Metal Bellows Forming Processes

To find out more about our three production methods for forming metal bellows as well as key features, tolerances, applications, and featured products, click the links below or review our metal bellows comparison guide above to compare all three methods at once.

Size, Stroke, and Temperature Ranges

Attainable dimensions, stroke length, convolution length, and temperature ranges depend on the material and fabrication process used. Below are achievable ranges across all material and process types.

For more details by process type, view our Bellows Technology Comparison Guide from the link above.

Finishing Services

We also offer many added secondary finishing services to choose from to ensure your metal bellows achieve your desired look, feel, and performance expectations.

Quality Materials

Metal bellows can be produced using a variety of materials. Below are some common examples of materials used to produce metal bellows.

Available Certifications

Available applicable certifications include:

Have Questions?

Talk with our experts today and let us help you figure out the best solution.