Titanium Springs & Components

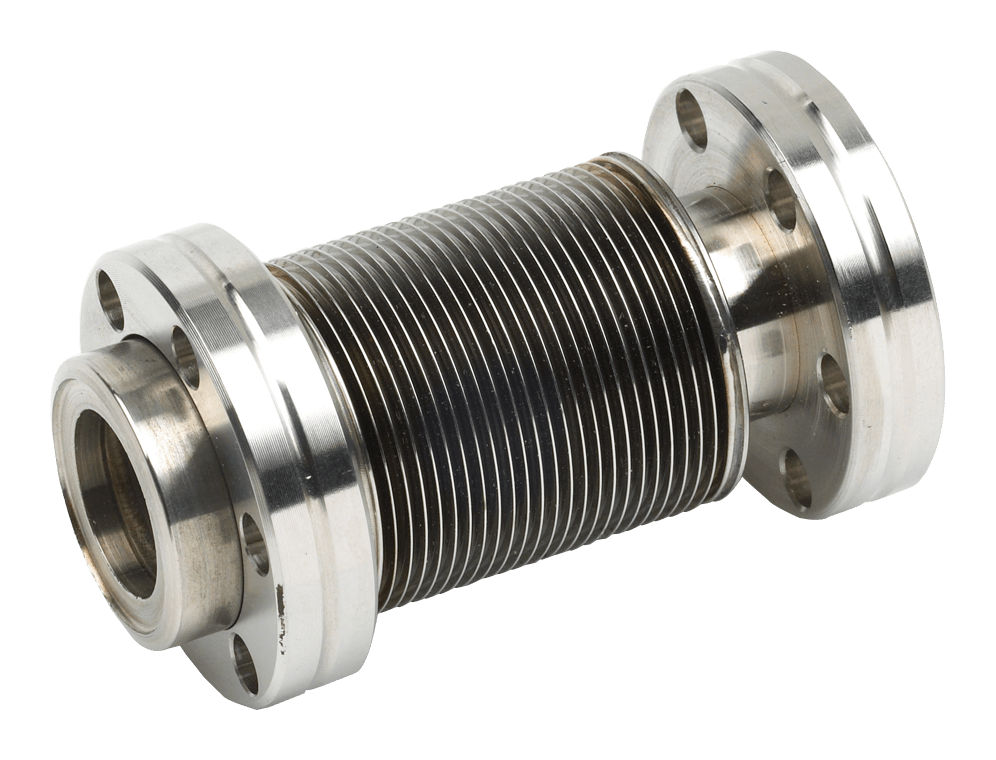

Titanium is a popular material choice for many different types of components, including springs, machined springs, metal bellows, and more. Titanium springs and other components have a number of characteristics, including strength and weight, that are ideal for critical applications such as aerospace springs that are used in commercial planes or even military aviation.

MW Components manufactures high quality titanium springs and other components at ISO9001 certified facilities in the United States. Request a quote to start your project with us.

Titanium Material Details

Extremely Strong & Lightweight

Titanium offers very high strength at low weight. It provides maximum force in a small space. It is both hot and cold “workable.” Titanium has a low torsion modulus and is heat treatable after forming. Its ability to be hot formed, enables the fabrication of larger springs.

Grades / Attributes

Grade 5 and Beta C, which is used extensively in the aerospace industry.

Spring Applications

Primarily aerospace including springs for airplane controls and landing gear. Also used for military and automotive applications. Other uses include implantable medical devices and compensator springs for oil and gas applications.

Material Benefits

Alternative material for stainless steel or Inconel®. Stainless steel is heavier, but much less expensive. Weight/cost attributes needs to be considered.

Considerations

Temperature attributes not as good as Inconel®, but superior to stainless steel.

Stock & Custom Titanium Parts

Contact Us

Need more information on stock or custom titanium springs or bellows? Contact us.